The agricultural sector plays a crucial role in global food production, but it also contributes significantly to environmental pollution. One key area where farmers can make a positive impact is in reducing harmful emissions from their machinery, particularly tractors. This article explores how proper management of tractor air filters can contribute to more sustainable farming practices.

The Importance of Air Filters in Tractors

Tractor air filters serve as the first line of defense against contaminants entering the engine. They prevent dust, debris, and other particles from causing damage to internal components. However, their role extends beyond mere engine protection. Properly maintained air filters can significantly reduce harmful emissions and improve fuel efficiency, thus contributing to more sustainable agricultural practices.

How Air Filters Impact Emissions and Fuel Efficiency

When a tractor air filter becomes clogged or dirty, it restricts the airflow to the engine. This causes the engine to work harder, consuming more fuel and producing more emissions. A clean, well-maintained air filter allows the engine to operate at peak efficiency, reducing fuel consumption and minimizing the release of harmful pollutants into the atmosphere.

Studies have shown that regularly replacing air filters can improve fuel efficiency by up to 10%. This not only reduces the carbon footprint of farming operations but also leads to significant cost savings over time.

Best Practices for Air Filter Maintenance

To maximize the benefits of air filters in reducing emissions, farmers should adopt a proactive approach to maintenance. Regular inspection is crucial, especially when operating in dusty conditions. Depending on the working environment, air filters may need to be cleaned or replaced more frequently than the manufacturer’s general recommendations.

When cleaning reusable air filters, it’s important to use appropriate methods that don’t damage the filter material. Additionally, many modern tractors are equipped with air filter monitoring systems that alert operators when maintenance is required.

Choosing the Right Air Filter: Quality and Types

Not all air filters are created equal. When selecting replacement filters, farmers should consider options that offer the best balance of filtration efficiency and engine performance: while premium filters may have a higher upfront cost, they often prove more economical in the long run due to extended service intervals and improved engine protection.

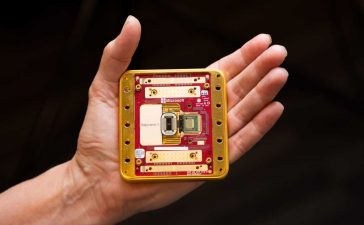

There are also three different types of engine air filters. The most common one is a so-called dry filter, composed on two coaxial filter cartridges are made of pleated sheets of cellulose or polyester fabric treated with synthetic resins.

Oil bath filters are usually used on small machines. They are made of wire mesh or synthetic material which is then immersed in a defined amount of engine lubricating oil so impurities are retained.

Lastly, there are the oil-bath filters with centrifugal prefilter, often used in combination to other types. The cyclone (or prefilter) is installed at the top of the main filter and consists of a tray containing oil where a hollow cartridge made of metal or nylon mesh is immersed. These filters are particularly used in very dusty environments.